يوجد في قلب مولد Max Ozone مولد الأوزون مع استخدام أنابيب تفريغ زجاجية خاصة عالية البورسليكات, الذي يمثل الأحدث, تكنولوجيا توليد الأوزون الأكثر تقدما, بتصميم حاصل على براءة اختراع يجمع بين التركيز العالي للأوزون, استهلاك منخفض للطاقة, واستقرار منقطع النظير.

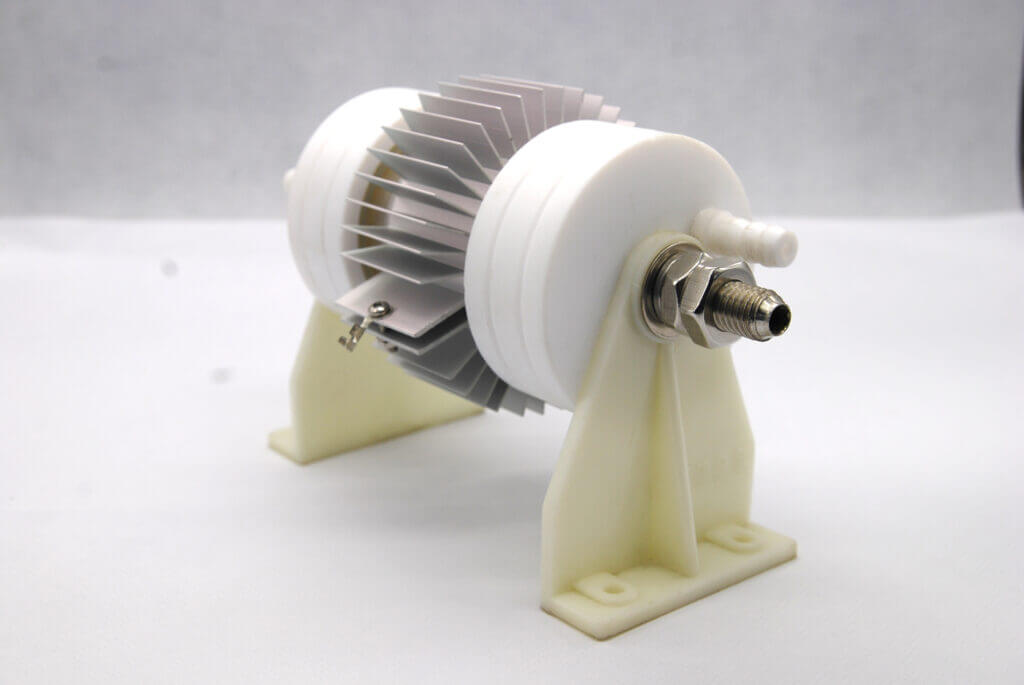

تم تصميم مولد الأوزون وفقًا لأوعية الضغط من الفئة الأولى, مجموعة من الماء البارد مصنوعة جزئيًا من الفولاذ المقاوم للصدأ عالي الجودة. المولد مزود من الخارج بخزان أسطواني, وهو مزود بنوافذ زجاجية من الجانبين لسهولة المراقبة. في الاسطوانة, يتم ترتيب عدد معين من أنابيب الفولاذ المقاوم للصدأ بشكل مضغوط ولحامها على لوحين فولاذيين ثابتين. تم تصميم مولد الأوزون الأقصى مع مراعاة عوامل السلامة مثل الضغط المنخفض وجهد الانهيار العالي للعازل.

تتكون مجموعة توليد الأوزون من أنابيب زجاجية خاصة منفصلة منزوعة الهيدروكسيل (أنابيب معزولة), أقطاب كهربائية عالية الجهد منفصلة من الفولاذ المقاوم للصدأ. يتم تشكيل فراغين للتفريغ الحلقي بين الأنبوب العازل والقطب الكهربائي عالي الجهد, ويتم توليد الأوزون عندما يتدفق الغاز عبر جانبي الأنبوب العازل.

النظر في استقرار العملية على المدى الطويل, يجب ألا يتجاوز جهد التشغيل للعازل 15% من تصنيف انهيار الجهد, وذلك لتقليل حدوث أعطال العازل أثناء توليد الأوزون, ولتقليل وقت توقف النظام, وقت الصيانة, واستهلاك قطع الغيار.

لا يتم تحديد أداء مولد الأوزون فقط بواسطة أنبوب التفريغ, ولكن أيضًا الجودة العالية لمجموعة وحدات إمداد الطاقة, نظام PLC ودرجة حرارة ماء التبريد.

تمثل وحدة إمداد الطاقة في Max Ozone أحدث التقنيات, والذي يوفر النظام الأكثر كفاءة من خلال التردد المتغير لضبط التغيرات في إنتاج الأوزون, وهو مناسب بشكل خاص لمولدات الأوزون ذات الإنتاج العالي. تم تصميم وحدة إمداد الطاقة بواسطة SUNCORN وتستخدم مكونات عالية الجودة مقدمة من الشركات المعروفة ذات الصلة في الصناعة. يعتمد تصميم جهد الإمداد على ضمان الاستقرار التشغيلي لجميع المعدات, مثل توزيع الطاقة, المحولات الخ.

خزانات مطلية خارجيًا مضادة لويتاكر, يتم قفل عدة مجموعات من أبواب الخزانات بشكل مستقل لسهولة الصيانة, وجميع أبواب الخزانات متشابكة لحماية سلامة الموظفين أثناء التشغيل العادي. تسمح واجهة الإنسان والآلة بالتشغيل اليدوي من خلال PLC المحلي والتحكم عن بعد بواسطة PLC واحد. يمكن عرض حالة التشغيل الحالية من خلال أضواء المؤشر والواجهة الرسومية.

تم تجهيز وحدة إمداد الطاقة بتوزيع / مقوم خاص, وحدة العاكس ومحول الجهد المعزز لتحويل ثلاث مراحل 50/60 طاقة التيار المتردد هرتز إلى مصدر طاقة عاكس أحادي الطور.

فضلاً عن ذلك, يوفر نظام التبريد جيد التهوية نقل الحرارة الأكثر كفاءة للطاقة الحرارية بسبب فقدان الطاقة في المكونات الكهربائية. الأسلاك بين المعدل, العاكس والمحول التصاعدي ممنوعان من الحافلات. يضمن التعشيق والمراقبة المستمرة للمعلمات المهمة استقرار النبات وحمايته. نظام تحكم متكامل مع PLC محلي للتحكم في مولد الأوزون ووحدة تزويد الطاقة.

ماكس مولد الأوزون

ماكس مولد الأوزون